What are the Mainstream Models of Resistors?

I. Introduction

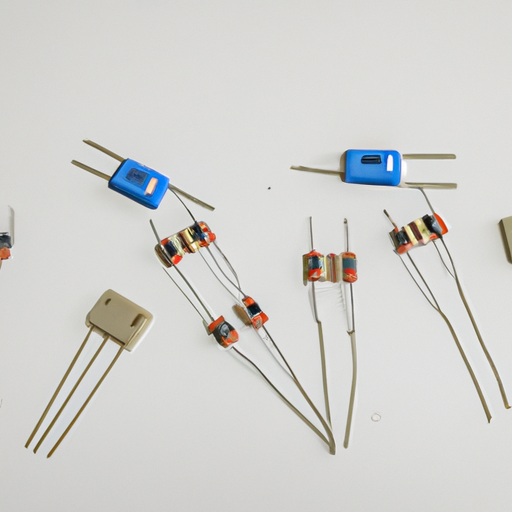

Resistors are fundamental components in electrical circuits, serving the essential function of limiting current flow and dividing voltages. They play a crucial role in a wide range of applications, from simple electronic devices to complex industrial machinery. Understanding the different types of resistors and their characteristics is vital for anyone involved in electronics, whether you're a hobbyist, student, or professional engineer. This article will explore the mainstream models of resistors, their construction, advantages, disadvantages, and applications.

II. Basic Concepts of Resistors

A. Ohm's Law

At the heart of resistor functionality lies Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. The formula is expressed as:

\[ V = I \times R \]

This relationship is fundamental in understanding how resistors operate within circuits.

B. Types of Resistance

Resistors can be categorized into two main types:

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in various applications.

2. **Variable Resistors**: These include potentiometers and rheostats, which allow for adjustable resistance values, making them useful in applications like volume controls and light dimmers.

III. Mainstream Models of Resistors

A. Carbon Composition Resistors

**Construction and Materials**: Carbon composition resistors are made from a mixture of carbon powder and a binding resin. The resistance value is determined by the ratio of carbon to resin.

**Advantages and Disadvantages**: They are inexpensive and can handle high energy pulses. However, they have a higher tolerance and lower stability compared to other types, making them less suitable for precision applications.

**Common Applications**: These resistors are often found in older electronic devices and applications where cost is a primary concern.

B. Carbon Film Resistors

**Manufacturing Process**: Carbon film resistors are created by depositing a thin layer of carbon on a ceramic substrate. The resistance is adjusted by cutting a helical groove in the film.

**Characteristics and Performance**: They offer better stability and tolerance than carbon composition resistors, making them suitable for more precise applications.

**Typical Uses**: Commonly used in consumer electronics, audio equipment, and general-purpose applications.

C. Metal Film Resistors

**Composition and Structure**: Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. The resistance is adjusted by trimming the metal layer.

**Precision and Stability**: These resistors are known for their high precision, low noise, and excellent temperature stability, making them ideal for sensitive applications.

**Applications in Electronics**: They are widely used in precision circuits, instrumentation, and audio applications.

D. Wirewound Resistors

**Design and Functionality**: Wirewound resistors consist of a wire (usually made of a nickel-chromium alloy) wound around a ceramic or fiberglass core.

**Power Ratings and Heat Dissipation**: They can handle high power ratings and are excellent at dissipating heat, making them suitable for high-power applications.

**Use Cases in High-Power Applications**: Commonly found in power supplies, amplifiers, and industrial equipment.

E. Thick Film Resistors

**Production Techniques**: Thick film resistors are made by screen printing a thick layer of resistive material onto a substrate.

**Advantages in Circuit Design**: They are cost-effective and can be produced in various shapes and sizes, making them versatile for different applications.

**Common Applications**: Used in consumer electronics, automotive applications, and as surface mount devices.

F. Thin Film Resistors

**Manufacturing Process and Materials**: Thin film resistors are produced by depositing a very thin layer of resistive material onto a substrate.

**Precision and Tolerance**: They offer superior precision and low temperature coefficients, making them ideal for high-frequency applications.

**Applications in High-Frequency Circuits**: Commonly used in RF circuits, precision measurement devices, and high-speed digital applications.

G. Surface Mount Resistors

**Overview of Surface Mount Technology (SMT)**: Surface mount resistors are designed to be mounted directly onto the surface of printed circuit boards (PCBs).

**Benefits and Limitations**: They save space and allow for automated assembly, but they can be more challenging to replace or repair.

**Usage in Modern Electronics**: Widely used in smartphones, computers, and other compact electronic devices.

H. Specialty Resistors

**Thermistors**: These are temperature-sensitive resistors that change resistance with temperature variations. They are commonly used in temperature sensing and control applications.

**Photoresistors**: Also known as LDRs (Light Dependent Resistors), these change resistance based on light exposure. They are often used in light-sensing applications like automatic lighting systems.

**Varistors**: Voltage-dependent resistors that protect circuits from voltage spikes. They are commonly used in surge protectors and voltage clamping applications.

IV. Factors Influencing Resistor Selection

When selecting a resistor for a specific application, several factors must be considered:

A. Resistance Value and Tolerance

The resistance value must match the circuit requirements, and the tolerance indicates how much the actual resistance can vary from the specified value.

B. Power Rating

The power rating indicates how much power the resistor can dissipate without overheating. It is crucial to choose a resistor with an appropriate power rating for the application.

C. Temperature Coefficient

This factor indicates how much the resistance changes with temperature. A low temperature coefficient is desirable for precision applications.

D. Environmental Considerations

Factors such as humidity, temperature extremes, and exposure to chemicals can affect resistor performance. Selecting a resistor that can withstand the environmental conditions is essential.

E. Size and Form Factor

The physical size and shape of the resistor can impact its suitability for a specific application, especially in compact electronic devices.

V. Conclusion

In summary, resistors are vital components in electronic circuits, and understanding the various mainstream models is essential for effective circuit design and application. From carbon composition to surface mount resistors, each type has its unique characteristics, advantages, and applications. Choosing the right resistor involves considering factors such as resistance value, power rating, and environmental conditions. As technology advances, we can expect to see further innovations in resistor technology, enhancing their performance and expanding their applications in the ever-evolving field of electronics.

VI. References

1. Academic Journals on Electronics and Circuit Design

2. Industry Standards for Resistor Specifications

3. Textbooks on Electronics and Circuit Design

By understanding the different types of resistors and their applications, you can make informed decisions in your electronic projects, ensuring reliability and performance in your designs.

What are the Mainstream Models of Resistors?

I. Introduction

Resistors are fundamental components in electrical circuits, serving the essential function of limiting current flow and dividing voltages. They play a crucial role in a wide range of applications, from simple electronic devices to complex industrial machinery. Understanding the different types of resistors and their characteristics is vital for anyone involved in electronics, whether you're a hobbyist, student, or professional engineer. This article will explore the mainstream models of resistors, their construction, advantages, disadvantages, and applications.

II. Basic Concepts of Resistors

A. Ohm's Law

At the heart of resistor functionality lies Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. The formula is expressed as:

\[ V = I \times R \]

This relationship is fundamental in understanding how resistors operate within circuits.

B. Types of Resistance

Resistors can be categorized into two main types:

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in various applications.

2. **Variable Resistors**: These include potentiometers and rheostats, which allow for adjustable resistance values, making them useful in applications like volume controls and light dimmers.

III. Mainstream Models of Resistors

A. Carbon Composition Resistors

**Construction and Materials**: Carbon composition resistors are made from a mixture of carbon powder and a binding resin. The resistance value is determined by the ratio of carbon to resin.

**Advantages and Disadvantages**: They are inexpensive and can handle high energy pulses. However, they have a higher tolerance and lower stability compared to other types, making them less suitable for precision applications.

**Common Applications**: These resistors are often found in older electronic devices and applications where cost is a primary concern.

B. Carbon Film Resistors

**Manufacturing Process**: Carbon film resistors are created by depositing a thin layer of carbon on a ceramic substrate. The resistance is adjusted by cutting a helical groove in the film.

**Characteristics and Performance**: They offer better stability and tolerance than carbon composition resistors, making them suitable for more precise applications.

**Typical Uses**: Commonly used in consumer electronics, audio equipment, and general-purpose applications.

C. Metal Film Resistors

**Composition and Structure**: Metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. The resistance is adjusted by trimming the metal layer.

**Precision and Stability**: These resistors are known for their high precision, low noise, and excellent temperature stability, making them ideal for sensitive applications.

**Applications in Electronics**: They are widely used in precision circuits, instrumentation, and audio applications.

D. Wirewound Resistors

**Design and Functionality**: Wirewound resistors consist of a wire (usually made of a nickel-chromium alloy) wound around a ceramic or fiberglass core.

**Power Ratings and Heat Dissipation**: They can handle high power ratings and are excellent at dissipating heat, making them suitable for high-power applications.

**Use Cases in High-Power Applications**: Commonly found in power supplies, amplifiers, and industrial equipment.

E. Thick Film Resistors

**Production Techniques**: Thick film resistors are made by screen printing a thick layer of resistive material onto a substrate.

**Advantages in Circuit Design**: They are cost-effective and can be produced in various shapes and sizes, making them versatile for different applications.

**Common Applications**: Used in consumer electronics, automotive applications, and as surface mount devices.

F. Thin Film Resistors

**Manufacturing Process and Materials**: Thin film resistors are produced by depositing a very thin layer of resistive material onto a substrate.

**Precision and Tolerance**: They offer superior precision and low temperature coefficients, making them ideal for high-frequency applications.

**Applications in High-Frequency Circuits**: Commonly used in RF circuits, precision measurement devices, and high-speed digital applications.

G. Surface Mount Resistors

**Overview of Surface Mount Technology (SMT)**: Surface mount resistors are designed to be mounted directly onto the surface of printed circuit boards (PCBs).

**Benefits and Limitations**: They save space and allow for automated assembly, but they can be more challenging to replace or repair.

**Usage in Modern Electronics**: Widely used in smartphones, computers, and other compact electronic devices.

H. Specialty Resistors

**Thermistors**: These are temperature-sensitive resistors that change resistance with temperature variations. They are commonly used in temperature sensing and control applications.

**Photoresistors**: Also known as LDRs (Light Dependent Resistors), these change resistance based on light exposure. They are often used in light-sensing applications like automatic lighting systems.

**Varistors**: Voltage-dependent resistors that protect circuits from voltage spikes. They are commonly used in surge protectors and voltage clamping applications.

IV. Factors Influencing Resistor Selection

When selecting a resistor for a specific application, several factors must be considered:

A. Resistance Value and Tolerance

The resistance value must match the circuit requirements, and the tolerance indicates how much the actual resistance can vary from the specified value.

B. Power Rating

The power rating indicates how much power the resistor can dissipate without overheating. It is crucial to choose a resistor with an appropriate power rating for the application.

C. Temperature Coefficient

This factor indicates how much the resistance changes with temperature. A low temperature coefficient is desirable for precision applications.

D. Environmental Considerations

Factors such as humidity, temperature extremes, and exposure to chemicals can affect resistor performance. Selecting a resistor that can withstand the environmental conditions is essential.

E. Size and Form Factor

The physical size and shape of the resistor can impact its suitability for a specific application, especially in compact electronic devices.

V. Conclusion

In summary, resistors are vital components in electronic circuits, and understanding the various mainstream models is essential for effective circuit design and application. From carbon composition to surface mount resistors, each type has its unique characteristics, advantages, and applications. Choosing the right resistor involves considering factors such as resistance value, power rating, and environmental conditions. As technology advances, we can expect to see further innovations in resistor technology, enhancing their performance and expanding their applications in the ever-evolving field of electronics.

VI. References

1. Academic Journals on Electronics and Circuit Design

2. Industry Standards for Resistor Specifications

3. Textbooks on Electronics and Circuit Design

By understanding the different types of resistors and their applications, you can make informed decisions in your electronic projects, ensuring reliability and performance in your designs.