What are the Manufacturing Processes of the Latest Adjustable Resistors?

I. Introduction

Adjustable resistors, commonly known as variable resistors, are essential components in electronic circuits, allowing for the modulation of electrical resistance. These devices play a crucial role in applications ranging from audio equipment to automotive systems, enabling fine-tuning of performance and functionality. Over the years, adjustable resistors have evolved significantly, incorporating advanced materials and manufacturing techniques to meet the demands of modern electronics.

II. Types of Adjustable Resistors

A. Potentiometers

Potentiometers are perhaps the most recognized type of adjustable resistor. They consist of a resistive element and a movable contact (wiper) that slides along the element, allowing users to adjust the resistance. Common applications include volume controls in audio devices and position sensors in various electronic systems.

B. Rheostats

Rheostats are similar to potentiometers but are typically used to control higher currents. They consist of a resistive wire wound around a core, with a sliding contact that adjusts the resistance. Rheostats are often found in applications such as light dimmers and motor speed controls.

C. Digital Potentiometers

Digital potentiometers represent a modern advancement in adjustable resistor technology. These devices use electronic components to adjust resistance values digitally, offering greater precision and control. They are widely used in applications requiring automated adjustments, such as in audio processing and signal conditioning.

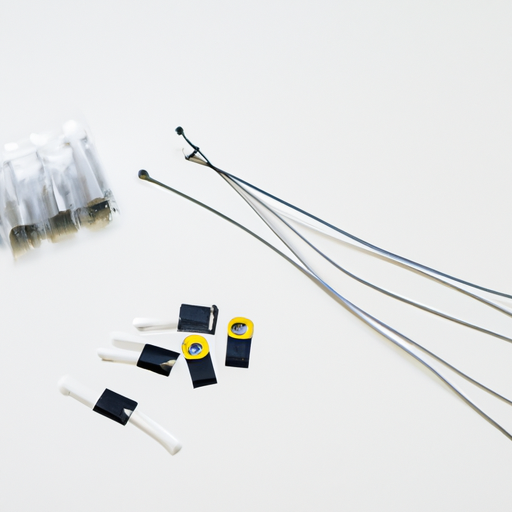

D. Trimmer Resistors

Trimmer resistors are small, adjustable resistors used for fine-tuning circuits. They are typically used in applications where precise adjustments are necessary, such as in calibration of electronic devices. Trimmer resistors are often found in radio frequency applications and precision measurement instruments.

III. Materials Used in Manufacturing Adjustable Resistors

A. Conductive Materials

The choice of conductive materials is critical in the manufacturing of adjustable resistors. Common materials include:

1. **Carbon Composition**: Often used in traditional potentiometers, carbon composition provides a cost-effective solution with reasonable performance.

2. **Metal Film**: Known for its stability and accuracy, metal film resistors are used in applications requiring precise resistance values.

3. **Wire-Wound**: This type of resistor is made by winding a resistive wire around a core, offering high power ratings and durability.

B. Insulating Materials

Insulating materials are essential for ensuring the reliability and safety of adjustable resistors. Common insulating materials include:

1. **Ceramic Substrates**: These provide excellent thermal stability and electrical insulation, making them ideal for high-performance applications.

2. **Plastic Casings**: Lightweight and cost-effective, plastic casings are commonly used in consumer electronics.

C. Coating Materials

Coating materials play a vital role in protecting adjustable resistors from environmental factors. Key coatings include:

1. **Protective Coatings**: These coatings shield resistors from moisture, dust, and other contaminants.

2. **Conductive Inks for Digital Potentiometers**: These inks are used in the manufacturing of digital potentiometers, allowing for precise control of resistance values.

IV. Manufacturing Processes

A. Design and Prototyping

The manufacturing process begins with design and prototyping. Engineers use Computer-Aided Design (CAD) software to create detailed designs of adjustable resistors. Prototyping techniques, such as 3D printing, allow for the rapid development of physical models, enabling engineers to test and refine their designs before mass production.

B. Material Preparation

Once the design is finalized, the next step involves material preparation. This includes sourcing high-quality conductive and insulating materials, followed by rigorous quality control checks. Pre-processing of materials, such as cutting and shaping, is also performed to ensure they meet the specifications required for production.

C. Component Fabrication

The fabrication of components is a critical stage in the manufacturing process. Techniques used include:

1. **Screen Printing for Thin-Film Resistors**: This method involves applying a resistive material onto a substrate using a screen, allowing for precise control over the thickness and pattern of the resistive element.

2. **Wire Winding for Wire-Wound Resistors**: In this technique, a resistive wire is wound around a core to create the desired resistance value.

The assembly of mechanical components follows, which includes housing and casing assembly, as well as the integration of adjustment mechanisms.

D. Electrical Testing

After assembly, each adjustable resistor undergoes rigorous electrical testing. This includes measuring resistance values and assessing performance under varying conditions, such as temperature and humidity. These tests ensure that the resistors meet the required specifications and function reliably in their intended applications.

E. Quality Assurance

Quality assurance is a vital part of the manufacturing process. Inspection processes are implemented to identify any defects or inconsistencies in the products. Compliance with industry standards, such as ISO certifications, is also ensured to maintain product quality and reliability.

V. Innovations in Adjustable Resistor Manufacturing

A. Automation and Robotics

The integration of automation and robotics in the manufacturing process has significantly improved production efficiency. Automated systems can perform repetitive tasks with high precision, reducing the likelihood of human error and increasing output.

B. Smart Adjustable Resistors

The rise of the Internet of Things (IoT) has led to the development of smart adjustable resistors. These devices can be controlled remotely, allowing for real-time adjustments and monitoring. This innovation is particularly beneficial in applications such as smart home systems and industrial automation.

C. Sustainable Manufacturing Practices

As environmental concerns grow, manufacturers are increasingly adopting sustainable practices. This includes the use of eco-friendly materials and waste reduction techniques, such as recycling scrap materials and optimizing production processes to minimize waste.

VI. Challenges in Manufacturing Adjustable Resistors

Despite advancements in technology, manufacturers face several challenges in producing adjustable resistors.

A. Precision and Tolerance Issues

Maintaining precision and tolerance in the manufacturing process is critical, as even minor deviations can affect performance. Manufacturers must invest in high-quality materials and advanced testing methods to ensure consistency.

B. Supply Chain Disruptions

Global supply chain disruptions can impact the availability of raw materials, leading to delays in production. Manufacturers must develop robust supply chain strategies to mitigate these risks.

C. Meeting Diverse Market Demands

The growing demand for customized solutions presents a challenge for manufacturers. They must balance the need for standardization with the ability to offer tailored products to meet specific customer requirements.

VII. Future Trends in Adjustable Resistor Manufacturing

The future of adjustable resistor manufacturing is poised for exciting developments.

A. Advancements in Materials Science

Ongoing research in materials science is expected to yield new conductive and insulating materials that enhance performance and durability.

B. Increased Customization Options

As technology advances, manufacturers will likely offer more customization options, allowing customers to specify unique resistance values and configurations.

C. Growth of the Electric Vehicle and Renewable Energy Markets

The rise of electric vehicles and renewable energy technologies will drive demand for adjustable resistors in applications such as battery management systems and power electronics.

VIII. Conclusion

Adjustable resistors are vital components in modern electronic circuits, enabling precise control of resistance values. The manufacturing processes of these devices have evolved significantly, incorporating advanced materials and innovative techniques. As the industry continues to innovate, the future of adjustable resistors looks promising, with advancements in technology and sustainability paving the way for new applications and improved performance.

IX. References

1. Academic journals and articles on electronic components and materials science.

2. Industry reports on trends in resistor manufacturing and applications.

3. Manufacturer specifications and guidelines for adjustable resistors.

This comprehensive overview highlights the importance of adjustable resistors, their manufacturing processes, and the innovations shaping their future in the electronics industry.

What are the Manufacturing Processes of the Latest Adjustable Resistors?

I. Introduction

Adjustable resistors, commonly known as variable resistors, are essential components in electronic circuits, allowing for the modulation of electrical resistance. These devices play a crucial role in applications ranging from audio equipment to automotive systems, enabling fine-tuning of performance and functionality. Over the years, adjustable resistors have evolved significantly, incorporating advanced materials and manufacturing techniques to meet the demands of modern electronics.

II. Types of Adjustable Resistors

A. Potentiometers

Potentiometers are perhaps the most recognized type of adjustable resistor. They consist of a resistive element and a movable contact (wiper) that slides along the element, allowing users to adjust the resistance. Common applications include volume controls in audio devices and position sensors in various electronic systems.

B. Rheostats

Rheostats are similar to potentiometers but are typically used to control higher currents. They consist of a resistive wire wound around a core, with a sliding contact that adjusts the resistance. Rheostats are often found in applications such as light dimmers and motor speed controls.

C. Digital Potentiometers

Digital potentiometers represent a modern advancement in adjustable resistor technology. These devices use electronic components to adjust resistance values digitally, offering greater precision and control. They are widely used in applications requiring automated adjustments, such as in audio processing and signal conditioning.

D. Trimmer Resistors

Trimmer resistors are small, adjustable resistors used for fine-tuning circuits. They are typically used in applications where precise adjustments are necessary, such as in calibration of electronic devices. Trimmer resistors are often found in radio frequency applications and precision measurement instruments.

III. Materials Used in Manufacturing Adjustable Resistors

A. Conductive Materials

The choice of conductive materials is critical in the manufacturing of adjustable resistors. Common materials include:

1. **Carbon Composition**: Often used in traditional potentiometers, carbon composition provides a cost-effective solution with reasonable performance.

2. **Metal Film**: Known for its stability and accuracy, metal film resistors are used in applications requiring precise resistance values.

3. **Wire-Wound**: This type of resistor is made by winding a resistive wire around a core, offering high power ratings and durability.

B. Insulating Materials

Insulating materials are essential for ensuring the reliability and safety of adjustable resistors. Common insulating materials include:

1. **Ceramic Substrates**: These provide excellent thermal stability and electrical insulation, making them ideal for high-performance applications.

2. **Plastic Casings**: Lightweight and cost-effective, plastic casings are commonly used in consumer electronics.

C. Coating Materials

Coating materials play a vital role in protecting adjustable resistors from environmental factors. Key coatings include:

1. **Protective Coatings**: These coatings shield resistors from moisture, dust, and other contaminants.

2. **Conductive Inks for Digital Potentiometers**: These inks are used in the manufacturing of digital potentiometers, allowing for precise control of resistance values.

IV. Manufacturing Processes

A. Design and Prototyping

The manufacturing process begins with design and prototyping. Engineers use Computer-Aided Design (CAD) software to create detailed designs of adjustable resistors. Prototyping techniques, such as 3D printing, allow for the rapid development of physical models, enabling engineers to test and refine their designs before mass production.

B. Material Preparation

Once the design is finalized, the next step involves material preparation. This includes sourcing high-quality conductive and insulating materials, followed by rigorous quality control checks. Pre-processing of materials, such as cutting and shaping, is also performed to ensure they meet the specifications required for production.

C. Component Fabrication

The fabrication of components is a critical stage in the manufacturing process. Techniques used include:

1. **Screen Printing for Thin-Film Resistors**: This method involves applying a resistive material onto a substrate using a screen, allowing for precise control over the thickness and pattern of the resistive element.

2. **Wire Winding for Wire-Wound Resistors**: In this technique, a resistive wire is wound around a core to create the desired resistance value.

The assembly of mechanical components follows, which includes housing and casing assembly, as well as the integration of adjustment mechanisms.

D. Electrical Testing

After assembly, each adjustable resistor undergoes rigorous electrical testing. This includes measuring resistance values and assessing performance under varying conditions, such as temperature and humidity. These tests ensure that the resistors meet the required specifications and function reliably in their intended applications.

E. Quality Assurance

Quality assurance is a vital part of the manufacturing process. Inspection processes are implemented to identify any defects or inconsistencies in the products. Compliance with industry standards, such as ISO certifications, is also ensured to maintain product quality and reliability.

V. Innovations in Adjustable Resistor Manufacturing

A. Automation and Robotics

The integration of automation and robotics in the manufacturing process has significantly improved production efficiency. Automated systems can perform repetitive tasks with high precision, reducing the likelihood of human error and increasing output.

B. Smart Adjustable Resistors

The rise of the Internet of Things (IoT) has led to the development of smart adjustable resistors. These devices can be controlled remotely, allowing for real-time adjustments and monitoring. This innovation is particularly beneficial in applications such as smart home systems and industrial automation.

C. Sustainable Manufacturing Practices

As environmental concerns grow, manufacturers are increasingly adopting sustainable practices. This includes the use of eco-friendly materials and waste reduction techniques, such as recycling scrap materials and optimizing production processes to minimize waste.

VI. Challenges in Manufacturing Adjustable Resistors

Despite advancements in technology, manufacturers face several challenges in producing adjustable resistors.

A. Precision and Tolerance Issues

Maintaining precision and tolerance in the manufacturing process is critical, as even minor deviations can affect performance. Manufacturers must invest in high-quality materials and advanced testing methods to ensure consistency.

B. Supply Chain Disruptions

Global supply chain disruptions can impact the availability of raw materials, leading to delays in production. Manufacturers must develop robust supply chain strategies to mitigate these risks.

C. Meeting Diverse Market Demands

The growing demand for customized solutions presents a challenge for manufacturers. They must balance the need for standardization with the ability to offer tailored products to meet specific customer requirements.

VII. Future Trends in Adjustable Resistor Manufacturing

The future of adjustable resistor manufacturing is poised for exciting developments.

A. Advancements in Materials Science

Ongoing research in materials science is expected to yield new conductive and insulating materials that enhance performance and durability.

B. Increased Customization Options

As technology advances, manufacturers will likely offer more customization options, allowing customers to specify unique resistance values and configurations.

C. Growth of the Electric Vehicle and Renewable Energy Markets

The rise of electric vehicles and renewable energy technologies will drive demand for adjustable resistors in applications such as battery management systems and power electronics.

VIII. Conclusion

Adjustable resistors are vital components in modern electronic circuits, enabling precise control of resistance values. The manufacturing processes of these devices have evolved significantly, incorporating advanced materials and innovative techniques. As the industry continues to innovate, the future of adjustable resistors looks promising, with advancements in technology and sustainability paving the way for new applications and improved performance.

IX. References

1. Academic journals and articles on electronic components and materials science.

2. Industry reports on trends in resistor manufacturing and applications.

3. Manufacturer specifications and guidelines for adjustable resistors.

This comprehensive overview highlights the importance of adjustable resistors, their manufacturing processes, and the innovations shaping their future in the electronics industry.